모네이드 케미컬스

Tel: 86-315-8309571

WhatsApp/WeChat/Mobile: 0086-15633399667

스카이프: janet-honest

주소: 2-7-523 Jidong Building Materials Tangshan, Hebei 064000 중국

|

화학명 |

비스-(나트륨 설포프로필)-디설파이드 |

|

동의어 |

SPS |

|

CAS 번호 |

27206-35-5 |

|

EINECS No. |

248-324-3 |

|

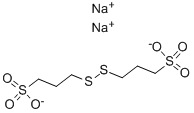

분자식 |

C6H12O6S4Na2 |

|

분자량 |

354.4 |

|

분자 구조 |

|

|

세부 |

Appearance: White powder Assay: 95% or 90% min Melting point: 197~198℃ Addition level : 0.01~0.02g/l Consumption (g/KAH): 0.5~0.8

|

|

주요 응용 프로그램 |

It is used as brightening agent & functional grain refinement agent for copper plating and combined with DAE, EDEP and so on.

|

Bis-(sodium sulfopropyl)-disulfide, commonly abbreviated as SPS, is a specialized organosulfur compound used primarily as a brightener additive in the electroplating industry—particularly for acid copper plating. It contains disulfide and sulfonate groups, making it highly effective in controlling deposit structure and appearance during metal plating.

1. Acid Copper Electroplating Brightener

SPS is widely used as a key brightener and grain refiner in acid copper baths, especially in the manufacturing of printed circuit boards (PCBs) and semiconductor components. It works synergistically with accelerators and suppressors to achieve uniform, high-gloss, fine-grained copper deposits.

2. Via-Filling and Microelectronic Applications

In advanced electronics manufacturing, SPS plays a crucial role in via-filling and damascene processes, promoting void-free copper deposition with excellent leveling characteristics—critical for high-density interconnects and IC fabrication.

3. Improved Deposit Morphology

SPS improves the microstructure of copper layers, resulting in smoother surfaces, better ductility, and lower internal stress. This is essential for ensuring mechanical reliability in electronic devices.

4. Stable and Water-Soluble Additive

Its high water solubility and chemical stability make it easy to integrate into plating baths with consistent performance across long production cycles.

5. Synergistic Performance

SPS works in conjunction with other additives like PEGs (suppressors) and thiourea derivatives (accelerators), enhancing overall control of plating speed, gloss, and deposit quality.