Moneide Chemicals

Tel: 86-315-8309571

WhatsApp/WeChat/Mobile: 0086-15633399667

Skype: janet-honest

Mail: sales@moneidechem.com

Address: 2-7-523 Jidong Building Materials Tangshan, Hebei 064000 China

DPS Sodium 3-[[(dimethylamino)thioxomethyl]thio]Propanesulphonate

|

Chemical Name |

Sodium 3-[[(dimethylamino)thioxomethyl]thio]propanesulphonate |

|

Synonyms |

N,N-Dimethyl-dithiocarbamyl propyl sulfonic acid sodium salt; DPS |

|

CAS No. |

18880-36-9 |

|

EINECS No. |

242-644-7 |

|

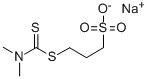

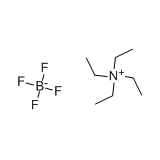

Molecular formula |

C6H12NNAO3S3 |

|

Molecular weight |

265.35 |

|

Molecular Structure |

|

|

Details |

Appearance: White glossy plate crystal Assay: 98.0% min. Addition level: 10~100mg/l Packing: 25kg or 5kg / fiber drum or as required

|

|

Main Application |

DPS is used as brightening agent in acid copper electroplating baths and has, in combination with polyethers and wetting agents, the effect of depositing a bright and ductile coating. A combination with other sulfur-containing brightening additives is also possible. For the chemical deposition of precious metals, DPS is used as a stabilizer to prevent wild deposition. |

Sodium 3-[[(dimethylamino)thioxomethyl]thio]propanesulphonate is a specialized organosulfur compound used primarily as a brightener and grain refiner in the electroplating industry, particularly for acid copper plating baths. This molecule contains a thiourea-derived functional group, a sulfonate group, and a dimethylamino group, making it highly effective in improving surface quality during metal deposition.

1. Electroplating Brightener (Copper Plating)

This compound is widely used as an additive in acid copper electroplating solutions, where it acts as a leveler and brightener. It helps produce smooth, fine-grained, shiny metal finishes—especially important in printed circuit board (PCB) manufacturing and decorative copper coatings.

2. Grain Refinement Agent

It enhances the microstructure of plated copper, promoting uniform grain size, improved mechanical properties, and reduced internal stress in the deposit. This leads to better electrical conductivity and durability in applications such as electronic connectors.

3. Additive in Electronic Manufacturing

Due to its high performance in controlling deposit morphology, this compound is critical in the production of semiconductor components, microelectronic circuits, and via filling in PCBs, where precision and smoothness are essential.

4. Synergistic Use with Other Plating Agents

It is often used in combination with other plating additives such as accelerators and suppressors to fine-tune the plating bath behavior. Its effectiveness enhances process control and consistency in high-speed plating operations.

5. High Solubility and Stability

Its water-soluble sulfonate group provides excellent bath compatibility and stability, allowing for consistent performance over long plating cycles and easy incorporation into aqueous systems.