Welcome to Tangshan Moneide Trading Co., Ltd.

Moneide Chemicals

Tel: 0086-315-8309571

WhatsApp/WeChat/Mobile: 0086-15633399667

Skype: janet-honest

Mail: sales@moneidechem.com

Address: 2-7-523 Jidong Building Materials Commercial Center, Tangshan, Hebei 064000 China

High-Quality Electroplating Chemicals Trusted Electroplating Chemicals Manufacturers

- Time of issue:Jul . 08, 2025 09:13

(Summary description)Tangshan Moneide Trading Co., Ltd. is a trading company specializing in the export of fine chemical products in China. Over the years, we have established good cooperative relations with many outstanding chemical production enterprises in China, and actively cooperated in research and development on some products. Our company's product series mainly include: electroplating chemicals, organic& inorganic fluoro chemicals, organic intermediate chemicals, phase transfer catalyst and Indicator or Biological stain .

- Categories:Company dynamic

- Author:

- Origin:

- Time of issue:2019-12-30 10:55

- Views:

(electroplating chemicals)

Electroplating chemicals play a pivotal role in surface finishing, offering enhanced corrosion resistance, improved electrical conductivity, and aesthetic appeal to a diverse range of products. The global market for electroplating chemicals

Technological progress has revolutionized the function and efficiency of electroplating baths. Modern solutions exhibit remarkable throwing power and throwing index, reducing material consumption by up to 25%. In electronics plating, high-purity nickel and gold chemistries now reach defect rates below 0.1%, directly improving yield and reliability in microelectronic components.

Choosing the right partner among global electroplating chemicals manufacturers requires careful examination of product range, innovation leadership, and sustainability credentials. The following table highlights essential metrics for leading suppliers:

Evaluating these manufacturers based on responsiveness, innovative capabilities, and environmental certifications helps tailor procurement to sector-specific needs and sustainable policies.

Not all production environments conform to off-the-shelf formulations. The rise of bespoke electroplating chemicals and other electroplating chemicals has transformed how industries approach quality benchmarks and unique substrate challenges. Customization options can include pH-adjusted proprietary baths, low-cyanide or cyanide-free alternatives, and specific ion-exchange systems for sensitive applications like medical device plating.

Electroplating chemicals are indispensable in industries ranging from automotive to aerospace, electronics to jewelry, delivering measurable performance and longevity. In 2023, nearly 65% of automotive fasteners in North America employed trivalent chromium baths, reducing hazardous wastes by over 40% compared to hexavalent alternatives. Electronics manufacturers now depend on advanced copper and nickel baths for reliable solderability and conductivity in printed circuit boards (PCBs).

Maintaining consistent quality in electroplating operations necessitates close adherence to both internal metrics and evolving regulatory mandates, such as REACH, RoHS, and local emission standards. Industry data notes that more than 85% of top-tier manufacturers have incorporated in-line spectroscopic analysis tools and automated pH/temperature controls to monitor bath composition in real time.

Strategic adoption of the right electroplating chemicals delivers a compelling return on investment via improved part durability, lower defect rates, and streamlined compliance. With the sector set to surpass USD 24 billion in global value by 2030, organizations that partner with experienced electroplating chemicals manufacturers position themselves for operational resilience and market leadership. Investing in process innovation, customization, and collaboration assures not only immediate performance gains but also sustainable, future-ready production practices.

(electroplating chemicals)

Introduction to Electroplating Chemicals and Their Strategic Importance

reached a valuation exceeding USD 18.6 billion in 2023 and is expected to witness a CAGR of 4.1% through 2030. Fueled by growth in the electronics, automotive, and jewelry industries, these chemicals are indispensable for fabricating challenging parts and meeting strict performance criteria across sectors.

Other electroplating chemicals such as base metal salts, additives, and brighteners serve unique purposes in tailoring finish quality and operational performance. Market reports indicate intensified R&D investment in green chemistries and waste minimization, echoing growing environmental mandates and customer-specific requirements.

Technological Advancements and Data Insights in Electroplating Chemistry

Data from a 2022 industry survey found that over 72% of manufacturers have upgraded to proprietary formulations incorporating nanostructured additives. Such additives confer thinner, more durable deposits and superior color uniformity. Automation, process monitoring, and data-driven adjustments have further lowered cycle time per part by up to 30%, maximizing resource efficiency.

Key Electroplating Chemicals Manufacturers: Comparative Analysis

Manufacturer

Core Products

Eco-Friendly Solutions

Lead Time

Customer Support

Market Share (2023)

Atotech

Nickel, Copper, Gold Salts, Additives

Yes (Comprehensive)

10-15 days

24/7 Global Support

21%

MacDermid Enthone

Base Metal Salts, Cleaners, Complexers

Partial Portfolio

12-18 days

Regional Offices

18%

Coventya

Additives, Brighteners, Precious Metal Salts

Selective

10-14 days

Project-Based

15%

Transene Company

Specialty Chemical Solutions

Yes (Niche)

6-10 days

Technical Consulting

9%

Customization and Specialized Solutions in Electroplating Chemicals

According to recent sectoral studies, 57% of manufacturers cite custom chemical formulations as essential to optimizing cycle times and achieving fine-tuned mechanical properties. Niche scenarios—such as plating extremely small-diameter wires or advanced electronics components—often require modifications in surfactant balance, particle dispersal, and carrier chemistry.

Collaborating directly with research-driven suppliers or electroplating chemicals manufacturers accelerates the implementation of tailored process controls and enhances throughput, especially in high-mix, low-volume production lines.

Industrial Applications and Success Cases

A notable success case involves an electronics OEM increasing line yield from 92% to 98.7% after reformulating silver-plating baths using high-stability anti-tarnish additives. In the medical sector, the introduction of sulfamate nickel baths for implantable device contacts improved mechanical wear resistance by up to 27%, supporting both patient safety and regulatory standards.

These cases underscore the transformative impact of optimized chemicals and continual partnership with leading electroplating chemicals manufacturers for persistent process improvement.

Quality Control and Regulatory Considerations

Compliance drives a shift toward lead-free, low-cadmium, and non-cyanide chemistries, aligned with stricter management of effluent discharge and worker safety. Certification under ISO 9001:2015 and ISO 14001:2015 has now become a market standard among reputable suppliers, signifying a commitment to continual improvement and responsible stewardship.

Conclusion: Unlocking Competitive Advantage with Electroplating Chemicals

FAQS on electroplating chemicals

Q: What are electroplating chemicals?

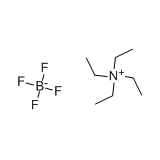

A: Electroplating chemicals are specialized solutions used to deposit a metal coating onto a conductive surface through electrolytic processes. These chemicals typically include metal salts, acids, and additives. They ensure the desired finish and properties on plated products.

Q: Why do manufacturers use different types of electroplating chemicals?

A: Manufacturers use various electroplating chemicals to achieve specific coating properties like hardness, corrosion resistance, or color. Different metals and applications require distinct chemical formulations. This versatility caters to diverse industrial needs.

Q: What are "Other Electroplating Chemicals" used for?

A: "Other Electroplating Chemicals" refer to additional additives, brighteners, or auxiliary chemicals supporting the main plating process. They enhance the quality, appearance, and durability of electroplated surfaces. These can include wetting agents, cleaners, or leveling agents.

Q: How do I choose reliable electroplating chemicals manufacturers?

A: Look for manufacturers with a proven track record, quality certifications, and positive client feedback. Assess their product range, technical support, and willingness to customize solutions. Comparing samples and consulting with industry peers also helps.

Q: Are electroplating chemicals safe to handle?

A: Electroplating chemicals can be hazardous if improperly handled due to their corrosive or toxic nature. Always follow the manufacturer's safety instructions, use protective gear, and ensure proper ventilation. Proper storage and disposal are also essential for safety.