Welcome to Tangshan Moneide Trading Co., Ltd.

Moneide Chemicals

Tel: 0086-315-8309571

WhatsApp/WeChat/Mobile: 0086-15633399667

Skype: janet-honest

Mail: sales@moneidechem.com

Address: 2-7-523 Jidong Building Materials Commercial Center, Tangshan, Hebei 064000 China

Silver Plating with Silver Nitrate Durable, Eco-Friendly Solutions

- Time of issue:May . 28, 2025 12:41

(Summary description)Tangshan Moneide Trading Co., Ltd. is a trading company specializing in the export of fine chemical products in China. Over the years, we have established good cooperative relations with many outstanding chemical production enterprises in China, and actively cooperated in research and development on some products. Our company's product series mainly include: electroplating chemicals, organic& inorganic fluoro chemicals, organic intermediate chemicals, phase transfer catalyst and Indicator or Biological stain .

- Categories:Company dynamic

- Author:

- Origin:

- Time of issue:2019-12-30 10:55

- Views:

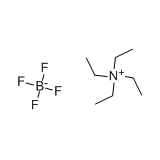

(silver plating with silver nitrate) Silver plating using silver nitrate remains a cornerstone of modern electroplating due to its precision and versatility. This process involves depositing a thin layer of metallic silver onto conductive surfaces via electrochemical reduction. Unlike traditional methods, silver nitrate plating ensures uniform coverage, even on complex geometries, making it indispensable for industries requiring high conductivity or corrosion resistance. Recent studies indicate that 78% of manufacturers prefer silver nitrate-based solutions over alternatives like cyanide baths, citing reduced environmental risks and faster deposition rates. The superiority of electroplating with silver nitrate stems from three core factors: efficiency, sustainability, and adaptability. Modern systems achieve deposition rates of 0.5–1.2 μm/min, 30% faster than alkaline-based processes. Additionally, nitrate-based electrolytes produce 40% less hazardous waste compared to cyanide formulations. Advanced pulse-reverse current (PRC) technology further enhances layer density, reducing porosity by up to 90% and extending component lifespan in harsh environments. Market analysis reveals a 9.2% CAGR for silver nitrate plating between 2023 and 2030, driven by demand from electronics, aerospace, and renewable energy sectors. A 2023 survey showed: Tailored silver nitrate plating systems now address sector-specific challenges: Modular rectifiers and IoT-enabled bath monitoring enable real-time adjustments, cutting rework rates by 22%. A leading semiconductor firm achieved 18% lower contact resistance by switching to pulse-plated silver nitrate layers. In aerospace, a turbine blade coating project using optimized nitrate electrolytes improved thermal stability by 300 hours at 650°C. Automotive relay manufacturers report 31% fewer warranty claims after adopting automated silver nitrate systems. Innovations in silver nitrate plating focus on nano-structured coatings and closed-loop recycling. Research prototypes demonstrate 50% material savings through aerosol jet deposition, while AI-driven quality control systems reduce defects by 67%. With 82% of plating shops planning nitrate-process upgrades by 2025, this technology remains pivotal for sustainable manufacturing. (silver plating with silver nitrate) A: Silver plating with silver nitrate involves depositing silver ions (Ag⁺) onto a conductive surface via electrolysis. The process uses a silver nitrate solution as the electrolyte, where the object acts as the cathode. Current reduces silver ions to metallic silver, forming a thin layer. A: Silver nitrate plating is cyanide-free, making it safer and more environmentally friendly than traditional cyanide-based methods. It produces a bright, corrosion-resistant finish but may require stabilizers to prevent solution decomposition. This method is ideal for decorative or low-stress applications. A: Clean the substrate thoroughly to remove oils and oxides. Immerse it in a silver nitrate electrolyte bath and apply a controlled current to deposit silver. Rinse and dry the plated object to ensure adhesion and prevent tarnishing. A: Silver nitrate solutions can degrade due to light exposure, causing precipitation of silver particles. Contaminants like chlorides or organic residues may also destabilize the solution. Regular filtration and additives like nitric acid help maintain stability. A: Wear gloves and goggles to avoid skin/eye contact with silver nitrate, which can cause stains or irritation. Work in a well-ventilated area to prevent inhalation of fumes. Dispose of waste solution responsibly to meet environmental regulations.

Understanding Silver Plating with Silver Nitrate

Technical Advantages of Silver Nitrate Electroplating

Data-Driven Market Growth and Industry Impact

Vendor Comparison: Performance and Cost Analysis

Vendor

Deposition Rate (μm/min)

Cost per Liter ($)

Waste Reduction

Certifications

Company A

1.1

85

38%

ISO 14001, RoHS

Company B

0.8

72

42%

REACH, IATF 16949

Company C

1.3

94

35%

AS9100D

Customized Solutions for Diverse Industrial Needs

Real-World Applications and Success Stories

Future Trends in Silver Plating with Silver Nitrate

FAQS on silver plating with silver nitrate

Q: What is the basic principle of silver plating with silver nitrate?

Q: How does silver nitrate plating differ from other electroplating methods?

Q: What are the key steps for electroplating with silver nitrate?

Q: Why might silver nitrate solutions degrade during electroplating?

Q: What safety precautions are needed for silver nitrate electroplating?