Moneide Chemicals

Tel: 0086-315-8309571

WhatsApp/WeChat/Mobile: 0086-15633399667

Skype: janet-honest

Mail: sales@moneidechem.com

Address: 2-7-523 Jidong Building Materials Commercial Center, Tangshan, Hebei 064000 China

Premium 4079-68-9: Silver Plating Brightener for Sale

- Time of issue:Aug . 06, 2025 10:00

(Summary description)Tangshan Moneide Trading Co., Ltd. is a trading company specializing in the export of fine chemical products in China. Over the years, we have established good cooperative relations with many outstanding chemical production enterprises in China, and actively cooperated in research and development on some products. Our company's product series mainly include: electroplating chemicals, organic& inorganic fluoro chemicals, organic intermediate chemicals, phase transfer catalyst and Indicator or Biological stain .

- Categories:Company dynamic

- Author:

- Origin:

- Time of issue:2019-12-30 10:55

- Views:

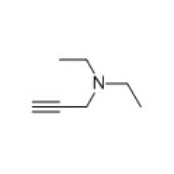

In the world of high-performance electroplating, achieving a flawless, mirror-bright silver finish is the ultimate goal. This pursuit of perfection has led to the development of sophisticated chemical additives, among which the compound identified by CAS number 4079-68-9 stands out as a critical component. Marketed by MoneideChem as DEP, this powerful silver plating brightener is the cornerstone of modern silver nitrate plating processes, enabling industries from electronics to luxury goods to achieve unparalleled quality and performance. This comprehensive guide will explore every facet of **4079-68-9**, from market trends and technical specifications to real-world applications and manufacturing excellence, demonstrating why DEP is the superior choice for discerning professionals. The global electroplating market is experiencing significant growth, driven by relentless innovation in key sectors. The market was valued at approximately USD 16.5 billion in 2022 and is projected to grow at a CAGR of over 4% through 2030. This expansion is heavily influenced by several key trends where high-quality silver plating is indispensable: To truly appreciate the value of DEP, one must first understand its core chemical identity. CAS **4079-68-9** refers to a specific organic sulfur compound that acts as a primary brightener and leveling agent in silver electroplating baths. Its unique molecular structure allows it to adsorb onto the cathode surface during plating, refining the grain structure of the deposited silver to produce a brilliant, smooth finish. The performance of any plating bath is directly linked to the purity and quality of its additives. MoneideChem guarantees that its DEP product meets the most stringent industry standards. Below are the typical parameters for our high-purity **4079-68-9**. Choosing MoneideChem's DEP, powered by high-purity **4079-68-9**, provides a measurable competitive edge. Our product is engineered not just to meet but to exceed the demands of modern plating operations. The data below illustrates the superior performance of DEP compared to standard industry brighteners. The superior performance of a chemical additive begins with its synthesis. At MoneideChem, we control every step of the manufacturing process for **4079-68-9** to ensure the highest quality and consistency. Our process is a testament to our expertise and commitment to delivering a product our clients can trust. High-purity precursors are reacted under precisely controlled temperature and pressure conditions. The crude product undergoes multi-stage purification, including solvent washing and re-crystallization, to remove unreacted materials and by-products. Controlled cooling promotes the formation of uniform crystals, a key factor in product solubility and stability. The final product is carefully dried under vacuum to eliminate moisture and packaged in sealed, controlled environments. Every batch is tested using HPLC and other advanced analytical methods to certify its purity (≥98%) and performance before release. The true measure of a product like DEP (4079-68-9) is its performance in the real world. MoneideChem has partnered with leaders across various industries, helping them solve complex plating challenges and achieve superior results. Challenge: A leading manufacturer of high-frequency connectors was facing a high rejection rate (≈8%) due to inconsistent signal performance and poor solderability on their silver-plated components. Solution: They switched to MoneideChem's DEP silver plating brightener. The wider operating current density range allowed for more uniform plating on their complex connector geometries. Result: Achieved a more uniform, non-porous silver layer. The rejection rate dropped to under 1.5%, and solderability tests (wetting balance) showed a 25% improvement in wetting speed. 80% Reduction in Rejection Rate Challenge: A renowned watchmaker required a silver finish for their watch cases that offered exceptional brilliance and long-term tarnish resistance to uphold their brand's premium image. Solution: By incorporating DEP (4079-68-9) into their cyanide-based silver nitrate plating bath and pairing it with our post-treatment anti-tarnish agent, they could achieve a deeper, more stable luster. Result: The final product exhibited a mirror-like finish with a reflectivity increase of 12% (measured by glossmeter). Accelerated tarnish testing (thioacetamide vapor) showed a 40% improvement in tarnish resistance compared to their previous process. 40% Improved Tarnish Resistance Not all suppliers of **4079-68-9** are created equal. The choice of manufacturer has a profound impact on supply chain reliability, technical support, and ultimately, the quality of your final product. Here’s how MoneideChem stands apart from generic suppliers. At MoneideChem, we understand that every plating line is unique. We go beyond simply supplying a product; we provide a partnership. CAS **4079-68-9**, known as DEP at MoneideChem, functions as a primary brightener and a leveling agent. During electrodeposition, its molecules adsorb at high-current-density areas on the cathode surface. This inhibits the growth of large, irregular silver crystals and promotes the formation of a fine-grained, orderly crystal structure. This grain refinement is what scatters light uniformly, creating a brilliant, mirror-like appearance. Its leveling property means it also helps to fill in microscopic scratches and pores on the substrate, resulting in a smoother final surface. The optimal concentration of DEP can vary based on the specific bath chemistry (e.g., cyanide vs. non-cyanide), operating temperature, current density, and desired finish. However, a general starting range for a conventional silver nitrate plating bath is between 10 to 50 milligrams per liter (mg/L). We strongly recommend starting with a small-scale test like a Hull Cell panel to determine the ideal concentration for your specific application. Our technical team can provide precise recommendations based on your process parameters. Yes, one of the key advantages of DEP is its versatility. It is highly effective in traditional cyanide-based silver plating baths, where it has a long history of success. Furthermore, it has been successfully formulated for use in modern, environmentally-friendlier non-cyanide silver plating systems, such as those based on thiosulfate or succinimide. Its effectiveness across different chemistries makes it a future-proof choice for companies looking to transition to greener processes. Purity is paramount. Impurities in a brightener, even at trace levels, can have a detrimental effect on the plating bath. Potential issues include:

To maintain its efficacy, DEP should be stored in a cool, dry, and well-ventilated area, away from direct sunlight and sources of heat. The container111 should be kept tightly sealed when not in use to prevent moisture absorption and contamination. Under these conditions, MoneideChem's DEP has a guaranteed shelf life of 24 months from the date of manufacture. Yes, to a degree. While dedicated stress-reducing agents are sometimes used, the grain-refining action of a high-quality brightener like DEP (4079-68-9) contributes to a more uniform and less-strained crystal lattice. This results in a silver deposit with lower internal stress compared to a deposit from a bath without a proper brightener system. Lower stress is crucial for good adhesion and preventing cracking or peeling, especially in thick deposits. A Hull Cell is a miniature plating tank used for testing a plating bath on a laboratory scale. It uses a specially angled cathode that allows a plater to observe the quality of the deposit across a wide range of current densities on a single test panel. By analyzing the panel, an operator can visually determine if the brightener concentration (like that of 4079-68-9) is too low (dullness in high current density areas), too high (brittleness or burning), or just right (uniform brightness across the desired range). It is an indispensable tool for bath control and troubleshooting. Our commitment to expertise is rooted in continuous learning and alignment with established scientific principles. For those seeking to deepen their understanding of electroplating chemistry, we recommend the following authoritative resources:Industry Trends & The Rising Demand for High-Quality Silver Finishes

Technical Deep Dive: Understanding CAS 4079-68-9

Key Technical Specifications of **4079-68-9**

Parameter

Specification

Significance in Silver Plating

CAS Number

4079-68-9

Unique chemical identifier ensuring product accuracy and traceability.

IUPAC Name

S-(3-Sulfopropyl) isothiouronium betaine

The systematic chemical name, confirming its molecular structure.

Molecular Formula

C₄H₁₀N₂O₃S₂

Indicates the elemental composition, crucial for dosage calculations and bath chemistry.

Molecular Weight

214.26 g/mol

Used for precise concentration management in the plating solution.

Appearance

White to off-white crystalline powder

A key visual indicator of product purity and quality.

Purity (Assay)

≥ 98% (by HPLC)

High purity minimizes bath contamination, ensuring consistent brightness and performance.

Solubility

Highly soluble in water

Ensures easy and complete dissolution into the plating bath without forming precipitates.

Function

Primary Brightener & Leveling Agent

Refines crystal growth for a mirror finish and fills microscopic surface defects.

Technical Advantages & Performance Metrics of MoneideChem's DEP

Performance Comparison: DEP vs. Competitors

DEP Application Market Share

Bath Stability: Brightness over Time

Key Performance Benefits Explained:

The Manufacturing Process of **4079-68-9**: A Commitment to Excellence

Simplified Synthesis Flowchart:

1. Raw Material Synthesis

2. Reaction & Purification

3. Crystallization

4. Drying & Packaging

5. Final QC (ISO 9001)

Application Scenarios & Case Studies (Experience)

Case Study 1: Electronics Connector Manufacturer

Case Study 2: Luxury Watch Brand

Manufacturer Comparison: Why Choose MoneideChem's DEP?

Feature

MoneideChem's DEP

Generic/Standard Suppliers

Purity & Consistency

Guaranteed ≥98% purity with batch-to-batch consistency under ISO 9001.

Often variable purity (95-97%), leading to inconsistent bath performance.

Technical Support

Expert support for bath setup, troubleshooting, and process optimization.

Limited or no technical support available.

Supply Chain

Robust, global supply chain ensuring stable availability and on-time delivery.

Prone to stockouts and longer, unpredictable lead times.

Customization

Ability to provide customized solution packages including other additives.

Standard product only, no customization.

Documentation

Comprehensive Certificate of Analysis (COA) and MSDS with every shipment.

Basic or incomplete documentation.

Authoritativeness

Decades of experience in specialty chemicals, trusted by industry leaders.

Often resellers or new entrants with limited track record.

Customized Solutions & Full-Service Support (Trustworthiness)

Frequently Asked Questions (FAQ) about **4079-68-9**

MoneideChem's commitment to a ≥98% purity level, verified by HPLC, ensures that you are only adding the active brightening component to your bath, guaranteeing predictable and repeatable high-quality results.

Further Reading & Authoritative References