모네이드 케미컬스

Tel: 86-315-8309571

WhatsApp/WeChat/Mobile: 0086-15633399667

스카이프: janet-honest

주소: 2-7-523 Jidong Building Materials Tangshan, Hebei 064000 중국

3-S-이소티우로늄 프로필 설포네이트

|

화학명 |

3-S-이소티우로늄 프로필 설포네이트 |

|

동의어 |

3-[(Aminoiminomethyl)thio]-1-propanesulfonic acid;UPS |

|

CAS 번호 |

21668-81-5 |

|

EINECS No. |

242-644-7 |

|

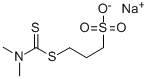

분자식 |

C4H10N2O3S2 |

|

분자량 |

265.35 |

|

분자 구조 |

|

|

세부 |

모습: White crystal 시험:95.0% min. Secondary constituents: 3-Hydroxypropane-1-Sulfonic acid; Water Solubility(at20℃): Water:4% Methanol:<0.5% Ethanol:<0.5% Addition level : 10~100mg/l Packing: 25kg or 5kg / fiber drum or as required

|

|

주요 응용 프로그램 |

UPS is used for the deposition of bright, ductile copper coatings in combination with polyethylene glycols and non-ionic surfactants. The employment of UPS is also possible in other acid electroplating baths for silver and palladium deposition.

|

3-S-Isothiuronium Propyl Sulfonate is a water-soluble organosulfur compound containing both isothiuronium and sulfonate functional groups. This unique structure gives it strong metal surface affinity, electrochemical activity, and water compatibility, making it especially useful in electroplating and microelectronics manufacturing.

1. Brightener in Acid Copper Electroplating

This compound is primarily used as a brightener and leveling agent in acid copper electroplating baths, particularly for printed circuit boards (PCBs) and semiconductor applications. It improves the smoothness, brightness, and uniformity of copper deposits, ensuring high-quality finishes.

2. Via-Fill and Microfeature Enhancement

In microelectronics, it contributes to via-filling and trench-plating, helping achieve void-free, dense copper deposits in fine structures. Its action supports uniform plating, essential for reliable interconnects and multilayer board fabrication.

3. Additive in Metal Finishing Formulations

Due to its strong metal-binding ability, 3-S-Isothiuronium Propyl Sulfonate is also used in formulations for metal surface treatment, promoting adhesion and improving surface quality in decorative or functional coatings.

4. Synergistic Performance with Other Plating Agents

It works synergistically with other components such as suppressors (e.g., PEG), accelerators, and levelers, enhancing control over deposit characteristics during high-speed and pulse plating processes.

5. High Water Solubility and Process Stability

Its excellent water solubility and chemical stability make it easy to handle in industrial-scale processes, ensuring consistent plating performance across extended production runs.