Welcome to Tangshan Moneide Trading Co., Ltd.

Moneide Chemicals

Tel: 0086-315-8309571

WhatsApp/WeChat/Mobile: 0086-15633399667

Skype: janet-honest

Mail: sales@moneidechem.com

Address: 2-7-523 Jidong Building Materials Commercial Center, Tangshan, Hebei 064000 China

Cyanide Electroplating Solutions Durable & Eco-Safe Metal Coating

- Time of issue:5 月 . 14, 2025 12:51

(Summary description)Tangshan Moneide Trading Co., Ltd. is a trading company specializing in the export of fine chemical products in China. Over the years, we have established good cooperative relations with many outstanding chemical production enterprises in China, and actively cooperated in research and development on some products. Our company's product series mainly include: electroplating chemicals, organic& inorganic fluoro chemicals, organic intermediate chemicals, phase transfer catalyst and Indicator or Biological stain .

- Categories:Company dynamic

- Author:

- Origin:

- Time of issue:2019-12-30 10:55

- Views:

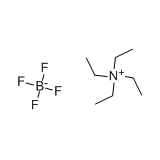

(cyanide in electroplating) Cyanide-based electrolytes remain fundamental to industrial electroplating, particularly for depositing precious metals. Potassium cyanide electroplating solutions enable 94-97% current efficiency in gold plating operations, outperforming many alternative chemistries. The cyanide ion acts as both complexing agent and conductive medium, facilitating uniform metal distribution even on complex geometries. Modern cyanide electroplating processes demonstrate three key technical advantages: Field data from aerospace manufacturers shows cyanide-based zinc plating delivers 2,200-2,500 hours salt spray resistance compared to 1,500 hours from cyanide-free systems. Specialized cyanide electroplating formulations address specific industrial requirements: A major automotive supplier reduced plating line energy consumption by 22% through optimized cyanide zinc baths. In jewelry manufacturing, potassium cyanide electroplating enabled 92% material utilization versus traditional methods. Modern closed-loop systems achieve 99.6% cyanide destruction efficiency through advanced oxidation processes. Automated monitoring maintains workplace air quality below 4.7ppm CN⁻ (OSHA PEL: 5ppm). Recent developments in cyanide electroplating focus on nanoparticle integration and pulse-reverse current techniques. These innovations promise 15-20% reduction in cyanide consumption while maintaining deposition quality, positioning cyanide-based processes as sustainable solutions for precision plating applications. (cyanide in electroplating) A: Cyanide acts as a complexing agent in electroplating, stabilizing metal ions (like gold or silver) in solution to ensure even deposition on the substrate. It also improves conductivity and reduces oxidation during the process. A: Yes, alternatives like acid-based baths or non-cyanide alkaline solutions are used, though cyanide electroplating remains popular for its efficiency and superior finish in specific applications. A: Potassium cyanide is highly toxic and requires strict safety protocols, including proper ventilation, protective gear, and waste treatment. Adherence to regulations minimizes risks in controlled environments. A: Cyanide-based baths offer faster deposition, better adhesion, and compatibility with diverse metals. For某些 critical industries (e.g., aerospace), its performance often outweighs risks when managed properly. A: Potassium cyanide provides a stable alkaline bath and higher solubility compared to sodium cyanide, making it ideal for high-precision plating processes like gold or silver coating.

The Critical Role of Cyanide in Modern Electroplating

Technical Superiority of Cyanide Electroplating Systems

Manufacturer Performance Comparison

Vendor

KCN Concentration (g/L)

Deposition Rate (µm/min)

Cost per Liter ($)

PlatingSolutions Pro

45-60

1.8-2.2

18.50

ElectroChem Masters

55-75

2.0-2.5

22.75

Advanced Surface Tech

40-50

1.5-1.9

16.90

Tailored Electroplating Solutions

Industrial Implementation Case Studies

Environmental Compliance and Worker Safety

Advancing Cyanide Electroplating Technology

FAQS on cyanide in electroplating

Q: What is the role of cyanide in electroplating?

Q: Are there alternatives to cyanide electroplating?

Q: Is potassium cyanide electroplating safe?

Q: Why is cyanide electroplating still used despite safety concerns?

Q: How does potassium cyanide differ from other cyanides in electroplating?