Welcome to Tangshan Moneide Trading Co., Ltd.

Moneide Chemicals

Tel: 0086-315-8309571

WhatsApp/WeChat/Mobile: 0086-15633399667

Skype: janet-honest

Mail: sales@moneidechem.com

Address: 2-7-523 Jidong Building Materials Commercial Center, Tangshan, Hebei 064000 China

Acid Copper Electroplating Solutions Bright & Durable Coatings

- Time of issue:Haz . 08, 2025 20:43

(Summary description)Tangshan Moneide Trading Co., Ltd. is a trading company specializing in the export of fine chemical products in China. Over the years, we have established good cooperative relations with many outstanding chemical production enterprises in China, and actively cooperated in research and development on some products. Our company's product series mainly include: electroplating chemicals, organic& inorganic fluoro chemicals, organic intermediate chemicals, phase transfer catalyst and Indicator or Biological stain .

- Categories:Company dynamic

- Author:

- Origin:

- Time of issue:2019-12-30 10:55

- Views:

(acid copper electroplating) Acid copper electroplating utilizes copper sulfate electrolytes with sulfuric acid to deposit high-purity copper layers onto conductive substrates. The electrochemical reaction occurs when direct current passes through the electrolyte bath, with copper cations (Cu²⁺) reducing to metallic copper at the cathode. Key electrolyte components include 40-100 g/L copper sulfate and 150-300 g/L sulfuric acid, maintained at 20-30°C. Proprietary organic additives like polyethylene glycol and bis-(3-sulfopropyl)-disulfide control deposition kinetics, ensuring uniform thickness distribution across complex geometries. Modern electroplating operations demand precise control over multiple technical parameters. Throw power exceeding 95% enables uniform coating in high-aspect-ratio components, while deposition rates of 10-15 μm/min accelerate production throughput. Industry benchmarks require stress values below 15 MPa to prevent micro-cracking in deposited layers. New formulations demonstrate exceptional throwing power exceeding conventional systems by 30%, critical for complex PCB vias below 0.1mm diameter. The chemistry enables average microhardness of 100-150 HV with tensile strength reaching 350 MPa, suitable for demanding engineering applications requiring both electrical conductivity and mechanical resilience. AR indicates aspect ratio; Class 5 represents highest brightness rating Formulation engineers optimize additives concentration based on application requirements. Semiconductor packaging utilizes copper sulphate electroplating with precisely controlled accelerator-to-suppressor ratios for void-free TSV filling at 10-12 μm thickness. Decorative applications employ copper electroplating brightener formulations with complexing agents generating mirror finishes of 350-500 GU gloss units. High-speed plating for automotive connectors requires specially designed levelers maintaining uniformity within ±5% at deposition rates exceeding 25 m/min. For complex aerospace components, reverse pulse plating programs deliver ±3% thickness tolerance across features spanning five orders of magnitude. A leading MEMS producer achieved yield improvement from 87% to 99.6% through optimized copper electroplating parameters. By precisely controlling convection patterns and brightener concentration gradients, defect density decreased from 125 to under 3 units/cm². The implementation reduced material consumption by 28% while maintaining resistivity of 1.72 μΩ·cm – equivalent to wrought copper standards. Continuous monitoring of organic breakdown products maintained bath lifetime exceeding 15 turnover periods, decreasing hazardous waste generation by 35% annually compared to traditional processes. High-volume connector manufacturing required cycle time reduction while maintaining coating uniformity. Modified acid copper plating chemistry featuring multi-component levelers and proprietary surfactants enabled 58% throughput increase while maintaining critical conductivity specifications. The reformulated process achieved deposition rates of 35 μm/min with thickness variation below 8% across complex terminal geometries. Accelerated corrosion testing demonstrated 1,200 hours to white corrosion in ASTM B117 testing – exceeding automotive requirements by 400 hours. Material cost reduction reached 22% annually through optimized additive dosing and decreased rectification losses. Advanced methodologies integrate machine learning with electroplating science. Recent developments include real-time brightener monitoring systems utilizing cyclic voltammetric stripping (CVS) for precise additive control to ±2% accuracy. Predictive models utilizing finite element analysis now anticipate throwing power efficiency in complex geometries with 97% accuracy. Upcoming formulations promise enhanced coverage at ultra-low current densities below 0.5 ASD, critical for nanowire structures in next-generation electronics. Such copper electroplating innovations will further improve sustainability metrics while enabling new applications demanding atomic-level precision. (acid copper electroplating) A: Acid copper electroplating deposits a highly conductive copper layer on substrates like PCBs and semiconductor components. It provides essential electrical conductivity and foundation for subsequent metal layers. Its excellent throwing power ensures even coverage on complex geometries. A: Copper electroplating brighteners adsorb onto the cathode surface to refine grain structure and enhance reflectivity. They suppress uncontrolled copper deposition while promoting uniform coverage. Organic compounds like thiourea derivatives are commonly used as key additives. A: Sulphuric acid increases electrolyte conductivity while reducing electrical resistance. It maintains bath stability and prevents hydrolysis of copper ions. Optimal concentration ranges from 10-20% by volume for efficient operations. A: Acid copper electroplating uses sulfate-based electrolytes with pH <3, enabling high-current efficiency (>95%). Alkaline processes use cyanide or pyrophosphate baths for superior adhesion on difficult substrates. Acid systems provide superior throwing power for through-holes and recesses. A: Chloride ions (30-90 ppm) activate brighteners while moderating organic additive performance. They prevent anode passivation and promote uniform dissolution. Precise control prevents dull deposits and enhances brightness synergistically.

principles

Understanding Acid Copper Electroplating Fundamentals

Critical Performance Metrics in Plating Processes

Competitive Analysis of Leading Plating Systems

Supplier

Brightener Efficiency

Operating Range (°C)

Deposition Rate (μm/min)

Void-Free Fill (AR)

Cost Efficiency

Supplier A

Class 4

22-28

12.5

10:1

$$$

Supplier B

Class 5

25-32

14.2

12:1

$$

Supplier C

Class 3

20-26

11.8

8:1

$$$$

Supplier D

Class 5

18-30

15.1

15:1

$$$

Tailored Solutions for Industry-Specific Requirements

Semiconductor Manufacturing Implementation

Automotive Connector Production Case

Future Enhancements in Acid Copper Plating

FAQS on acid copper electroplating

Q: What is acid copper electroplating primarily used for?

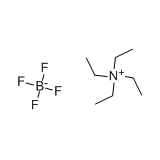

Q: How do copper electroplating brighteners function?

Q: Why is sulphuric acid added in copper sulphate electroplating baths?

Q: What distinguishes acid copper baths from alkaline copper plating processes?

Q: What role does chloride play in acid copper electroplating baths?