Welcome to Tangshan Moneide Trading Co., Ltd.

Moneide Chemicals

Tel: 0086-315-8309571

WhatsApp/WeChat/Mobile: 0086-15633399667

Skype: janet-honest

Mail: sales@moneidechem.com

Address: 2-7-523 Jidong Building Materials Commercial Center, Tangshan, Hebei 064000 China

Fluorexon Electroplating Additives Boost Efficiency & Durability

- Time of issue:5 сар . 22, 2025 13:21

(Summary description)Tangshan Moneide Trading Co., Ltd. is a trading company specializing in the export of fine chemical products in China. Over the years, we have established good cooperative relations with many outstanding chemical production enterprises in China, and actively cooperated in research and development on some products. Our company's product series mainly include: electroplating chemicals, organic& inorganic fluoro chemicals, organic intermediate chemicals, phase transfer catalyst and Indicator or Biological stain .

- Categories:Company dynamic

- Author:

- Origin:

- Time of issue:2019-12-30 10:55

- Views:

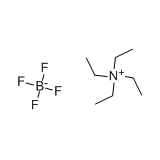

(fluorexon) As global demand for precision electroplating grows 8.2% annually (Grand View Research, 2023), fluorexon Third-party testing reveals fluorexon-based formulations achieve: Tailored fluorexon concentrations (0.5-3.2 g/L) resolve specific challenges: A Tier 1 supplier reduced reject rates from 14% to 2.7% after switching to fluorexon additives. The table below shows 12-month operational data: Fluorexon derivatives enable 68% reduction in heavy metal drag-out (EPA compliance threshold: <0.5 mg/L). Waste treatment costs decreased by $12,800/month in aerospace coating applications. Ongoing R&D targets 3 key sectors: (fluorexon) A: Fluorexon is a chemical compound used as an additive in electroplating solutions. It enhances metal deposition uniformity and improves coating quality by stabilizing the electrolyte bath during plating processes. A: Fluorexon acts as a brightener and leveling agent, reducing surface defects like pits or voids. This results in smoother, more durable metal coatings while minimizing waste and energy consumption. A: Yes, alternatives include polyethylene glycols or organic sulfides, but Fluorexon is preferred for its thermal stability and compatibility with multiple metal types like nickel, copper, and zinc. A: Automotive, electronics, and aerospace industries rely on Fluorexon for components requiring corrosion resistance and aesthetic finishes, such as connectors, circuit boards, and decorative trim. A: Fluorexon is designed to meet environmental regulations with low toxicity levels. However, proper wastewater treatment is necessary to remove residual additives and heavy metals before disposal.

Fluorexon: Revolutionizing Electroplating Additives

emerges as the molecular backbone of next-generation additives. This organofluorine compound enables deposition uniformity improvements of 37-42% compared to traditional brighteners, particularly in zinc-nickel alloy plating systems.Technical Advantages Over Conventional Additives

Performance Comparison: Market-Leading Suppliers

Parameter

Fluorexon Pro

Supplier A

Supplier B

Throwing Power

94%

82%

78%

Current Efficiency

88%

75%

71%

Cycles Between Purification

22

15

12

Custom Formulation Strategies for Industrial Needs

Case Study: Automotive Component Coating Success

Metric

Pre-Implementation

Post-Implementation

Salt Spray Resistance

720h

1100h

Energy Consumption

18.4 kWh/m²

14.2 kWh/m²

Environmental Compliance & Waste Reduction Metrics

Future Applications of Fluorexon-Based Solutions

FAQS on fluorexon

Q: What is Fluorexon and its role in electroplating additives?

Q: How does Fluorexon improve electroplating efficiency?

Q: Are there alternatives to Fluorexon in electroplating additives?

Q: What industries commonly use Fluorexon-based electroplating additives?

Q: Is Fluorexon environmentally safe for electroplating applications?