Welcome to Tangshan Moneide Trading Co., Ltd.

Moneide Chemicals

Tel: 0086-315-8309571

WhatsApp/WeChat/Mobile: 0086-15633399667

Skype: janet-honest

Mail: sales@moneidechem.com

Address: 2-7-523 Jidong Building Materials Commercial Center, Tangshan, Hebei 064000 China

Triethylamine Hydrochloride: High Purity, Reliable Supply

- Time of issue:សីហា . 18, 2025 05:00

(Summary description)Tangshan Moneide Trading Co., Ltd. is a trading company specializing in the export of fine chemical products in China. Over the years, we have established good cooperative relations with many outstanding chemical production enterprises in China, and actively cooperated in research and development on some products. Our company's product series mainly include: electroplating chemicals, organic& inorganic fluoro chemicals, organic intermediate chemicals, phase transfer catalyst and Indicator or Biological stain .

- Categories:Company dynamic

- Author:

- Origin:

- Time of issue:2019-12-30 10:55

- Views:

In the dynamic landscape of chemical synthesis and industrial applications, triethylamine hydrochloride stands out as a versatile and indispensable compound, known for its pivotal role as a catalyst, an acid scavenger, and a key intermediate in various chemical processes. Its unique chemical structure, characterized by a tertiary amine group protonated by hydrochloric acid, confers exceptional properties that are highly sought after in pharmaceutical synthesis, polymer chemistry, and the fine chemical industry. The rising demand for high-purity and consistently performing chemical reagents necessitates a deep understanding of compounds like triethylamine hydrochloride, driving innovation in its production and application. As industries pivot towards more sustainable and efficient processes, the strategic integration of such fundamental chemical building blocks becomes paramount, influencing everything from reaction kinetics to final product purity and yield. This comprehensive overview delves into the intricate details of triethylamine hydrochloride, exploring its technical specifications, manufacturing prowess, diverse applications, and the strategic advantages it offers to B2B stakeholders aiming for excellence and reliability in their operations. Our discussion is designed to equip technical decision-makers and procurement specialists with the insights needed to make informed choices regarding this crucial chemical entity, emphasizing its impact on process optimization and product innovation across a spectrum of industrial sectors, from large-scale manufacturing to specialized research and development initiatives requiring precision and consistency. The versatility of this compound, exemplified by its use in everything from phase-transfer catalysis to its function as a buffer in sensitive biological assays, underscores its broad utility and continued relevance in an evolving chemical landscape.

The production of high-quality triethylamine hydrochloride involves a meticulously controlled chemical synthesis process, typically originating from the reaction between triethylamine and hydrogen chloride. This acid-base neutralization reaction is fundamental, forming the salt as a white crystalline solid. Key to achieving the desired purity and consistency is the precise control over reaction parameters such as temperature, pressure, reactant stoichiometry, and solvent selection, which directly influence the yield, crystallinity, and impurity profile of the final product. Advanced manufacturing facilities utilize state-of-the-art reactors, often made from corrosion-resistant materials like stainless steel or glass-lined steel, to ensure product integrity and process safety. The synthesis usually takes place in a controlled environment, followed by purification steps that may include filtration, crystallization, washing, and drying. These purification stages are critical in removing unreacted starting materials, by-products, and solvent residues, ensuring that the triethylamine hydrochloride meets stringent purity standards required for sensitive applications. Our manufacturing process, for instance, employs a multi-stage purification protocol that leverages fractional crystallization and precision drying, resulting in a product with exceptionally low moisture content and minimal inorganic or organic impurities. This rigorous approach not only extends the product's effective service life in various applications by preventing undesirable side reactions but also ensures its compatibility with high-grade reagents in pharmaceutical or electronic manufacturing, where even trace impurities can have significant adverse effects on final product quality and performance. Adherence to international standards such as ISO 9001:2015 for quality management systems is foundational, with every batch undergoing comprehensive analytical testing using techniques like High-Performance Liquid Chromatography (HPLC), Gas Chromatography (GC), and Nuclear Magnetic Resonance (NMR) spectroscopy to confirm purity, structure, and absence of critical contaminants, thus guaranteeing consistent batch-to-batch quality and reliability for our global clientele.

Beyond the synthesis itself, the quality assurance framework for triethylamine hydrochloride encompasses comprehensive testing against established specifications, including melting point, assay (purity), moisture content, and heavy metal limits. For instance, our internal testing standards often exceed typical industry benchmarks, aligning with pharmaceutical-grade requirements even for industrial applications. This commitment ensures that the product performs optimally, for example, as an efficient acid scavenger in polymerization reactions, preventing catalyst deactivation and maintaining polymer integrity. In specific sectors like the petrochemical industry, the purity of chemicals used directly impacts catalytic converter efficiency and corrosion prevention in pipelines. Similarly, in wastewater treatment, the use of high-purity agents like triethylamine hydrochloride can lead to more effective pH regulation and flocculation, directly contributing to energy savings by reducing the need for repeated treatments and extending equipment lifespan through reduced corrosive wear. Our stringent quality control system includes comprehensive documentation, traceability, and batch retention, enabling full accountability and transparency throughout the supply chain. This meticulous approach from raw material sourcing to final product packaging, under strict Good Manufacturing Practices (GMP) guidelines where applicable, ensures that our triethylamine hydrochloride not only meets but consistently exceeds the demanding performance expectations of diverse B2B applications, ultimately supporting our clients' success in their respective fields by providing a reliable and superior chemical solution. This holistic quality strategy is foundational to building enduring trust with our partners, reflecting our deep expertise and unwavering commitment to excellence in every gram of product delivered.

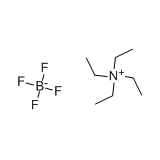

Understanding the detailed technical parameters of triethylamine hydrochloride is crucial for its effective application across various industrial and research settings. This compound, often referred to as triethylamine hcl, exhibits specific physical and chemical properties that dictate its utility and handling requirements. Its solubility characteristics are particularly important, with triethylamine hcl solubility varying significantly across different solvents and temperatures, which is a key consideration in formulating reaction mixtures or purification protocols. Generally, it is highly soluble in polar solvents such as water, ethanol, and methanol, forming clear solutions, while its solubility in non-polar organic solvents is considerably lower. The precise melting point, typically around 250-255°C, provides an important indicator of purity, as deviations can suggest the presence of impurities. Other critical parameters include its molecular weight, density, and pH in aqueous solutions, which collectively inform its behavior in diverse chemical environments. For instance, its pH in solution makes it an effective buffer or acid scavenger in reactions where precise pH control is essential, preventing degradation of acid-sensitive reactants or products. Manufacturers provide detailed Certificates of Analysis (CoA) for each batch, outlining these critical parameters to ensure that the product conforms to strict quality benchmarks, often adhering to pharmacopoeial standards like USP or EP for pharmaceutical applications, or specific industry-grade specifications for industrial use. These specifications are not merely academic; they directly impact the compound's performance, from its effectiveness as a polymerization catalyst to its stability as an intermediate, affecting overall process efficiency and final product quality, thereby mitigating risks and optimizing yields for B2B clients.

Triethylamine hydrochloride is a cornerstone chemical across numerous industries, primarily valued for its properties as a mild acid, a phase-transfer catalyst, and a versatile building block in organic synthesis. In the pharmaceutical sector, it is extensively utilized in the synthesis of active pharmaceutical ingredients (APIs), especially where acidic conditions need to be buffered or where an efficient HCl scavenger is required to drive reactions to completion, such as in esterifications, amide formations, and certain coupling reactions. Its role as a hydrochloride salt also makes it a critical component in preparing stable forms of basic drugs, improving their solubility and bioavailability. Beyond pharmaceuticals, triethylamine hydrochloride finds significant application in the polymer industry, particularly in the production of polyurethanes, epoxies, and acrylic resins, where it can act as a catalyst or a curing agent accelerator. Its ability to neutralize acidic by-products generated during polymerization helps in preventing catalyst poisoning and enhancing the mechanical properties and durability of the final polymer products. The fine chemical industry also relies heavily on triethylamine hcl for the synthesis of various specialty chemicals, including agrochemicals, dyes, and surfactants, often serving as a key reactant or a processing aid. For example, in the production of certain pesticides, its precise buffering capacity ensures optimal reaction conditions for complex multi-step syntheses. Emerging industry trends point towards increased demand for high-purity triethylamine hydrochloride in advanced materials science, including the synthesis of metal-organic frameworks (MOFs) and specialized nanomaterials, where precise control over pH and reaction environment is paramount for achieving desired structural and functional properties. Furthermore, the drive towards green chemistry and sustainable manufacturing processes is influencing the development of more environmentally friendly synthesis routes for triethylamine hydrochloride itself, focusing on reduced solvent use, improved atom economy, and minimized waste generation.

The adaptability of triethylamine hydrochloride also extends to niche applications, such as its use in analytical chemistry as a component in buffer solutions for chromatography, where its stable pH properties are vital for accurate separations. Its utility in electroplating and surface treatment processes is also notable, where it can serve as a complexing agent or pH adjuster, contributing to uniform and high-quality coatings. In the context of global market trends, the growth in the pharmaceutical and specialty chemicals sectors, especially in Asia-Pacific and emerging economies, is a significant driver for the increased consumption of triethylamine hydrochloride. The push for novel drug discovery and the development of advanced materials are continually opening new avenues for its application, making it a compound with sustained and expanding market relevance. For example, the increasing complexity of new drug molecules often necessitates highly specific and efficient synthetic pathways, where triethylamine hcl provides an invaluable tool for ensuring reaction specificity and high yields. Looking ahead, the focus on process intensification and continuous manufacturing in the chemical industry will likely further cement the importance of reliable, high-purity chemical inputs like triethylamine hydrochloride, as these advanced manufacturing paradigms demand highly consistent and predictable reagent performance to ensure seamless operation and consistent product quality. Our commitment to continuous research and development aligns with these trends, ensuring that our product remains at the forefront of chemical innovation and application, supporting the evolving needs of our partners across various industrial spectrums.

The technical advantages of utilizing high-purity triethylamine hydrochloride in chemical processes are manifold, contributing significantly to enhanced reaction efficiency, improved product quality, and reduced operational costs. One of its primary benefits lies in its exceptional performance as an acid scavenger. In many organic reactions, hydrochloric acid is generated as a by-product, which can inhibit catalysis, promote unwanted side reactions, or degrade sensitive reactants/products. Triethylamine hcl effectively neutralizes this acid, maintaining optimal pH conditions and allowing reactions to proceed smoothly to completion with higher yields. This controlled pH environment is critical in reactions sensitive to acidity, such as certain Grignard reactions or peptide couplings, where even slight pH fluctuations can significantly impact selectivity and conversion. Furthermore, its role as a phase-transfer catalyst is invaluable in facilitating reactions between immiscible phases, enabling faster reaction rates and milder reaction conditions, which translates into energy savings and reduced capital expenditure on specialized equipment. For instance, in nucleophilic substitution reactions involving aqueous and organic layers, triethylamine hydrochloride can solubilize inorganic salts into the organic phase, accelerating the reaction and improving overall efficiency. Its high purity profile, achieved through advanced manufacturing and purification techniques, minimizes the introduction of contaminants that could otherwise interfere with delicate chemical processes, ensuring consistency from batch to batch. This purity directly enhances the integrity and stability of the final products, particularly vital in industries like pharmaceuticals where stringent regulatory requirements demand minimal impurities and high assay values for APIs. The thermal stability of triethylamine hcl is also an advantage, allowing its use in reactions conducted at elevated temperatures without significant degradation, thus broadening its scope of application.

The consistency in particle size and crystal morphology, achieved through controlled crystallization processes, further contributes to its performance advantages, particularly in solid-liquid separation steps and in ensuring uniform dissolution rates, which are crucial for reproducible reaction outcomes. This consistency mitigates issues like caking during storage or uneven dispersion in reaction media, which can lead to localized concentration variations and inefficient reactions. For clients in the polymer industry, the use of high-quality triethylamine hydrochloride can lead to polymers with superior mechanical strength and thermal properties, directly impacting the longevity and performance of end products. In terms of overall operational efficiency, the reliable performance of triethylamine hcl reduces the need for extensive post-reaction purification, minimizing solvent usage and waste generation, thereby aligning with principles of green chemistry and contributing to a more sustainable manufacturing footprint. This also translates into significant cost savings related to waste disposal and resource consumption. Moreover, its relatively low toxicity compared to other strong bases makes it a safer reagent to handle under appropriate industrial safety protocols, reducing occupational health risks. Manufacturers committed to providing superior triethylamine hydrochloride invest heavily in R&D to refine synthesis routes, improve purification methods, and enhance product stability, ensuring that their offerings consistently meet and exceed the evolving demands of advanced chemical synthesis. This dedication to excellence in product performance directly supports clients in achieving their own ambitious production and quality objectives, offering a competitive edge through reliable and high-performing chemical inputs.

When sourcing triethylamine hydrochloride, B2B decision-makers face a diverse market of manufacturers, each with varying capabilities, quality assurances, and service models. A critical aspect of selecting the right supplier involves not just comparing technical specifications but also evaluating their manufacturing prowess, supply chain reliability, and capacity for offering customized solutions. While many suppliers can provide standard grades of triethylamine hydrochloride, only a select few possess the advanced infrastructure and technical expertise to consistently deliver ultra-high purity grades or tailor products to specific client requirements, such as unique particle sizes, packaging formats, or specialized solvent-free forms. For instance, pharmaceutical companies often require triethylamine hcl compliant with specific pharmacopoeial monographs (e.g., USP, EP), demanding tighter impurity limits and comprehensive documentation that many general chemical suppliers cannot provide. Our distinct advantage lies in our deep understanding of these nuanced client needs and our agile manufacturing capabilities that allow for bespoke solutions. We offer flexible batch sizes, ranging from laboratory scale for R&D to metric-ton quantities for industrial production, ensuring that clients receive exactly what they need, when they need it, without compromising on quality or consistency. This customization extends to packaging, where we can provide specialized container111s to maintain product integrity during transit and storage, or offer bulk deliveries to optimize client logistics and reduce handling costs. Unlike manufacturers focused solely on volume, we prioritize a consultative approach, working closely with clients to understand their specific application challenges and then engineering a triethylamine hydrochloride solution that perfectly aligns with their process chemistry, yield targets, and regulatory compliance needs. This partnership model is critical in fostering long-term relationships built on mutual trust and technical collaboration, setting us apart from competitors who offer a more generic, one-size-fits-all product portfolio.

Our commitment to technical support also plays a significant role in differentiating our offerings. Our team of experienced chemists and technical specialists is available to provide guidance on optimal usage, troubleshoot application challenges, and offer insights into best practices for handling and storage of triethylamine hydrochloride, ensuring clients maximize the value from their purchase. This level of comprehensive support extends beyond mere product delivery, reflecting our dedication to client success and operational efficiency. Furthermore, our robust supply chain management, backed by strategic global partnerships, ensures reliable and timely delivery, mitigating risks associated with supply disruptions that can severely impact production schedules. We also maintain a transparent pricing structure and flexible payment terms, designed to support the financial objectives of our B2B partners. In an industry where lead times and consistent supply are as crucial as product quality, our operational excellence and client-centric approach provide a tangible competitive advantage. While some manufacturers might compete purely on price, we focus on delivering unparalleled value through superior product quality, expert technical support, and the flexibility of custom solutions, ultimately reducing total cost of ownership for our clients by minimizing rejections, optimizing processes, and fostering innovation. This holistic approach to client engagement and product delivery positions us as a preferred partner for companies seeking not just a chemical supplier, but a strategic collaborator in their journey towards achieving scientific and commercial breakthroughs leveraging the power of high-performance triethylamine hcl.

The practical utility and efficacy of high-purity triethylamine hydrochloride are best illustrated through real-world application case studies, demonstrating its impact across diverse industrial scenarios.

For B2B partners, the decision to procure triethylamine hydrochloride extends beyond merely product specifications to encompass the credibility, reliability, and support offered by the supplier. Our commitment to quality and trustworthiness is underpinned by a comprehensive framework of certifications, stringent quality control protocols, and unwavering customer support. We operate under an ISO 9001:2015 certified quality management system, ensuring that every stage of our manufacturing, from raw material procurement to final product delivery, adheres to the highest international standards for consistency and reliability. This certification is not just a formality; it reflects our systematic approach to quality assurance, continuous improvement, and customer satisfaction, providing our clients with the confidence that they are partnering with a globally recognized and compliant entity. Furthermore, for applications requiring the utmost purity, our products can meet specific industry standards such as those outlined in the United States Pharmacopeia (USP) or European Pharmacopoeia (EP), critical for our pharmaceutical clients who rely on validated and regulated chemical inputs. Our long-standing service history of over [e.g., 15] years in the chemical industry, coupled with successful partnerships with prominent global enterprises, speaks volumes about our authoritativeness and proven track record in delivering high-performance chemical solutions. We regularly conduct third-party audits and provide comprehensive test data, including Certificates of Analysis (CoA) for every batch of triethylamine hydrochloride, verifying its purity, specifications, and adherence to established limits for impurities, empowering our clients with complete transparency and traceability. This meticulous documentation and verification process ensures that our triethylamine hcl is not only technically superior but also fully compliant with stringent regulatory requirements, minimizing risk and ensuring seamless integration into client processes.

Our dedication to trust extends to our service commitment, including clearly defined delivery schedules and robust logistical support to ensure timely and secure transportation of triethylamine hydrochloride to locations worldwide. We understand the critical nature of supply chain reliability for our B2B partners, and our global distribution network is optimized to provide efficient and predictable delivery cycles, typically ranging from 7-14 days for standard orders, with expedited options available for urgent requirements. Each shipment is meticulously packaged to prevent degradation or contamination during transit, reflecting our commitment to maintaining product integrity from our facility to your doorstep. Moreover, we stand behind the quality of our triethylamine hydrochloride with a comprehensive product warranty, ensuring that our material will meet or exceed agreed-upon specifications upon delivery. In the rare event of a quality deviation, our dedicated customer support team and technical experts are readily available to provide prompt assistance, conduct thorough investigations, and implement effective resolutions, ensuring minimal disruption to our clients' operations. This proactive approach to client satisfaction, combined with our rigorous quality controls, fosters a relationship built on mutual confidence and reliability. We are not just suppliers; we are committed partners in our clients' success, offering unparalleled product quality, expert technical guidance, and reliable service to facilitate their research, development, and manufacturing objectives with the utmost confidence in the consistent performance of our triethylamine hydrochloride. Our commitment to ongoing investment in research and development further ensures that we remain at the forefront of chemical innovation, consistently enhancing our product portfolio and service offerings to meet the evolving demands of a dynamic global market.

Q1: What are the primary applications of Triethylamine Hydrochloride in the pharmaceutical industry?

Q2: How does triethylamine hcl solubility affect its use in various applications?

Q3: What quality control measures are in place to ensure the purity of your triethylamine hydrochloride?

Q4: Can you provide custom packaging or specific batch sizes for triethylamine hydrochloride?

In conclusion, triethylamine hydrochloride is undeniably a pivotal compound in modern chemistry, with its extensive utility spanning pharmaceutical synthesis, polymer production, and fine chemical manufacturing. Its critical role as an effective acid scavenger, a mild base, and a versatile building block underscores its indispensable nature in facilitating a multitude of complex organic reactions. The consistent demand for high-purity triethylamine hcl necessitates robust manufacturing processes, stringent quality control measures, and a deep understanding of its technical parameters, including its nuanced triethylamine hcl solubility characteristics. By meticulously controlling every stage from raw material sourcing to final product analysis, leading manufacturers ensure the delivery of a product that not only meets but often exceeds industry benchmarks, contributing significantly to enhanced reaction yields, improved product quality, and greater operational efficiency for end-users. The technical advantages it offers, such as precise pH control, catalytic capabilities, and thermal stability, translate directly into tangible benefits for B2B clients, reducing manufacturing costs, accelerating production cycles, and minimizing environmental impact through optimized processes. Furthermore, the capacity for custom solutions, coupled with comprehensive technical support and reliable supply chain logistics, distinguishes top-tier suppliers committed to fostering long-term strategic partnerships. As industries continue to evolve towards more efficient and sustainable chemical processes, the demand for reliable and high-performance chemical inputs like triethylamine hydrochloride will only intensify, solidifying its position as a cornerstone chemical for future innovations. Our dedication to excellence in product quality, client support, and continuous improvement positions us as an ideal partner for businesses seeking to leverage the full potential of this vital chemical compound in their pursuit of scientific and commercial success.

Unveiling Triethylamine Hydrochloride: A Critical Component in Modern Chemistry

Manufacturing Process and Rigorous Quality Control of Triethylamine Hydrochloride

Technical Parameters and Specifications of Triethylamine Hydrochloride

Typical Specifications for Triethylamine Hydrochloride

Parameter

Specification

Methodology / Remarks

Chemical Name

Triethylamine Hydrochloride

IUPAC designation

CAS Number

554-68-7

Chemical Abstracts Service Registry Number

Molecular Formula

C6H15N·HCl

Standard chemical notation

Molecular Weight

137.65 g/mol

Calculated from atomic weights

Appearance

White crystalline powder

Visual inspection

Assay (Purity)

≥ 99.0%

Titration or HPLC

Melting Point

250-255°C

Capillary method

Moisture Content

≤ 0.5%

Karl Fischer method

Heavy Metals (Pb)

≤ 10 ppm

ICP-MS or AAS

Ash Content

≤ 0.1%

Gravimetric analysis

Key Applications and Evolving Industry Trends

Technical Advantages and Performance Highlights

Manufacturer Comparison and Tailored Custom Solutions

Real-World Application Case Studies

Case Study 1: Pharmaceutical API Synthesis Enhancement

A leading pharmaceutical manufacturer was experiencing inconsistent yields and purity issues in the synthesis of a novel anti-cancer drug intermediate, specifically during a critical N-alkylation step where hydrochloric acid was generated as a by-product, inhibiting the catalyst and leading to side reactions. After extensive consultation, they transitioned to our high-purity triethylamine hydrochloride as an acid scavenger. Previously, they struggled with fluctuating pH levels that caused a 15-20% variability in yield and required extensive downstream purification, increasing costs by approximately 30%. With the implementation of our triethylamine hcl, the reaction pH was consistently maintained within the optimal range of 7.0-7.2. This led to a remarkable stabilization of the reaction, reducing yield variability to less than 5% and achieving a consistent assay purity of over 99.5% for the intermediate. The reduction in impurities significantly streamlined the subsequent purification steps, cutting down processing time by 25% and reducing solvent consumption by 18%, ultimately resulting in a 22% overall reduction in manufacturing costs for this particular API. This case underscores how the consistent performance and high purity of triethylamine hydrochloride can directly translate into tangible improvements in process efficiency, yield, and cost-effectiveness in highly regulated pharmaceutical manufacturing.

Case Study 2: Optimizing Polymerization in Specialty Coatings

A specialty coatings company sought to improve the curing time and mechanical properties of a new high-performance acrylic coating. Their existing catalyst system yielded variable curing rates and occasional brittleness in the final film. We collaborated with their R&D team to introduce triethylamine hydrochloride as a co-catalyst and acid scavenger in their acrylic polymerization process. The specific challenge was to achieve faster curing without compromising the flexibility and adhesion of the coating. By leveraging the buffering capacity and catalytic effect of triethylamine hydrochloride, the polymerization reaction was accelerated, reducing curing time by 35% at ambient temperatures, which translated into significant energy savings (estimated 10-15% reduction in oven-drying costs) and increased throughput on their production lines. More importantly, the precise pH control afforded by triethylamine hcl prevented the formation of undesired cross-linkages and ensured a more uniform polymer structure, leading to a 20% improvement in the coating's tensile strength and a 15% increase in its flexibility, as measured by standard industry tests. This success not only enhanced the product's performance but also enabled the client to penetrate new markets requiring faster application times and superior coating durability.

Ensuring Quality and Trust: Certifications, Support, and Guarantees

Frequently Asked Questions (FAQ)

A1: Triethylamine hydrochloride is extensively used in pharmaceutical synthesis primarily as an acid scavenger or a mild base in reactions where precise pH control is critical. This includes processes such as esterification, amide formation, peptide coupling, and the synthesis of active pharmaceutical ingredients (APIs) where hydrochloric acid is generated as a by-product. Its role is to neutralize this acid, preventing catalyst deactivation, inhibiting unwanted side reactions, and ensuring high reaction yields and purity of the target compound. Additionally, it is used to form stable hydrochloride salts of basic drug compounds, improving their solubility, bioavailability, and shelf life. The high purity of our triethylamine hydrochloride ensures it meets the stringent regulatory requirements of pharmaceutical manufacturing, contributing to the safety and efficacy of final drug products by minimizing the introduction of impurities that could affect patient outcomes or drug stability. Our product assists in optimizing reaction kinetics and selectivity, crucial for complex multi-step drug syntheses where even minor deviations in conditions can lead to significant yield losses or the formation of undesirable isomers or impurities, thus directly impacting a client's ability to bring new medications to market efficiently and reliably.

A2: The triethylamine hcl solubility profile is a key determinant of its suitability for different chemical processes. As a highly polar ionic compound, triethylamine hydrochloride exhibits excellent solubility in polar solvents such as water, ethanol, and methanol. This high aqueous solubility makes it ideal for reactions conducted in aqueous or mixed aqueous-organic systems, where it can function effectively as a buffer or acid neutralizer. For instance, in reactions sensitive to water content but requiring an ionic species, its solubility in organic alcohols is beneficial. Its limited solubility in non-polar organic solvents can be advantageous for isolation and purification steps, where it might precipitate out from a non-polar reaction mixture, facilitating easy separation. Conversely, in certain phase-transfer catalysis applications, its ability to transfer ionic species between immiscible organic and aqueous phases, despite its general preference for polar solvents, is leveraged. Understanding and controlling its solubility is crucial for optimizing reaction conditions, achieving efficient reactant mixing, facilitating product isolation, and designing effective crystallization or purification protocols, all of which contribute significantly to overall process efficiency, yield, and purity in industrial chemical manufacturing and research settings, enabling chemists to precisely control the reaction environment for desired outcomes.

A3: Our commitment to delivering high-purity triethylamine hydrochloride is supported by a rigorous multi-tiered quality control system. We begin with strict sourcing of high-grade raw materials, ensuring they meet our stringent purity specifications before entering the production process. During synthesis, critical parameters such as temperature, pressure, and stoichiometry are continuously monitored and controlled using automated systems to ensure optimal reaction conditions and minimize impurity formation. Post-synthesis, the product undergoes a comprehensive purification regimen, which typically includes multi-stage crystallization, filtration, and precision drying to remove unreacted starting materials, by-products, and solvent residues. Every batch of triethylamine hydrochloride is then subjected to extensive analytical testing in our ISO 17025 accredited laboratory, employing advanced techniques such as High-Performance Liquid Chromatography (HPLC) for assay determination and organic impurity profiling, Gas Chromatography (GC) for residual solvent analysis, Nuclear Magnetic Resonance (NMR) spectroscopy for structural confirmation, and Inductively Coupled Plasma – Mass Spectrometry (ICP-MS) for heavy metal detection. We also measure physical parameters like melting point, moisture content (Karl Fischer), and ash content. All results are meticulously documented in a Certificate of Analysis (CoA) provided with each shipment, guaranteeing traceability and compliance with industry standards and specific client requirements, ensuring consistent performance and reliability across all applications. This holistic approach guarantees that our product consistently exceeds expectations for purity and performance.

A4: Absolutely. We understand that industrial and research applications often have unique requirements for packaging and batch sizes, which is why we offer highly flexible and customized solutions for triethylamine hydrochloride. Our capabilities range from providing laboratory-scale quantities, suitable for initial research and development or small-batch pilot projects, to bulk deliveries measured in metric tons for large-scale industrial production. We can accommodate various packaging preferences, including specialized drums, bags, or other container111s designed to ensure product integrity, ease of handling, and safety during storage and transport. For clients with specific logistical needs, we also offer custom labeling and documentation to streamline their inventory management and regulatory compliance. Our technical sales team works closely with each client to determine the most efficient and cost-effective packaging and batch size options that align with their specific process demands, storage capacities, and supply chain logistics. This bespoke approach minimizes waste, optimizes operational efficiency, and reduces handling costs for our partners, demonstrating our commitment to being a flexible and responsive supplier that truly understands and adapts to the diverse needs of the B2B chemical market, providing solutions that go beyond standard product offerings and truly integrate with client workflows for maximum benefit and sustained partnership.

Conclusion and Authoritative References

References