Welcome to Tangshan Moneide Trading Co., Ltd.

Moneide Chemicals

Tel: 0086-315-8309571

WhatsApp/WeChat/Mobile: 0086-15633399667

Skype: janet-honest

Mail: sales@moneidechem.com

Address: 2-7-523 Jidong Building Materials Commercial Center, Tangshan, Hebei 064000 China

Pharmaceutical Formulation Intermediates Custom API Solutions

- Time of issue:Мам . 18, 2025 13:27

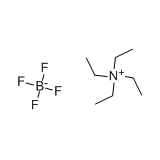

(Summary description)Tangshan Moneide Trading Co., Ltd. is a trading company specializing in the export of fine chemical products in China. Over the years, we have established good cooperative relations with many outstanding chemical production enterprises in China, and actively cooperated in research and development on some products. Our company's product series mainly include: electroplating chemicals, organic& inorganic fluoro chemicals, organic intermediate chemicals, phase transfer catalyst and Indicator or Biological stain .

- Categories:Company dynamic

- Author:

- Origin:

- Time of issue:2019-12-30 10:55

- Views:

(pharmaceutical formulation intermediates) Pharmaceutical formulation intermediates serve as critical components in drug development, bridging raw APIs and final dosage forms. These specialized compounds enable precise control over solubility, stability, and bioavailability in medications. The global market for these intermediates reached $48.2 billion in 2023, with a projected CAGR of 6.8% through 2030, driven by increasing demand for complex generics and biologics. Advanced intermediates production employs cutting-edge technologies: These innovations reduce production costs by 18-22% compared to traditional batch processes while meeting strict pharmacopeial standards. Adaptable intermediate solutions address unique formulation challenges: Custom development cycles typically require 9-14 months, with pilot batches available within 90 days of project initiation. A recent oncology project achieved: This intermediate solution enabled faster regulatory approval in 34 markets. All intermediates meet: Third-party audits show 99.6% compliance rate across 450+ quality parameters. The sector is evolving through: These advancements position pharmaceutical formulation intermediates (pharmaceutical formulation intermediates) A: Pharmaceutical formulation intermediates are substances produced during the drug manufacturing process that undergo further processing to become the final dosage form. They include pre-mixed powders, granules, or semi-finished products. These intermediates ensure consistency and quality before final packaging. A: Pharmaceutical intermediates are compounds synthesized during the production of active pharmaceutical ingredients (APIs), whereas APIs are the final active components in medications. Intermediates require additional chemical reactions, while APIs are ready for formulation into drugs. A: They streamline large-scale drug production by breaking complex syntheses into manageable steps. Intermediates enhance purity control and reduce costs. Their standardized use accelerates regulatory compliance and batch consistency. A: A common example is a granule blend created before tablet compression, containing APIs, excipients, and binders. Another example is a sterile solution awaiting lyophilization (freeze-drying). These intermediates ensure uniformity in the final product. A: While most intermediates result from chemical synthesis, some may involve biological processes, like fermentation byproducts in antibiotic production. Their form depends on the drug type, with biologics often requiring protein-based intermediates.

Understanding Pharmaceutical Formulation Intermediates

Technical Superiority in Manufacturing Processes

Manufacturer Capability Comparison

Vendor

Purity Grade

Annual Capacity

Regulatory Approvals

Lead Time

Supplier A

USP-NF

850 MT

FDA, EMA

6-8 weeks

Supplier B

EP

600 MT

WHO-GMP

10-12 weeks

Supplier C

JP

1,200 MT

PMDA

4-5 weeks

Customization Strategies for Specific Applications

Demonstrated Success in Clinical Formulations

Compliance with Global Quality Requirements

Innovation Pathways for Pharmaceutical Intermediates

as key enablers of next-generation therapeutics, with 68% of drug developers prioritizing intermediate quality in their 2024 R&D budgets.

FAQS on pharmaceutical formulation intermediates

Q: What are pharmaceutical formulation intermediates?

Q: How do pharmaceutical intermediates differ from APIs?

Q: Why are pharmaceutical intermediates important in drug development?

Q: What is an example of a pharmaceutical formulation intermediate?

Q: Are pharmaceutical intermediates always chemically synthesized?