Welcome to Tangshan Moneide Trading Co., Ltd.

Moneide Chemicals

Tel: 0086-315-8309571

WhatsApp/WeChat/Mobile: 0086-15633399667

Skype: janet-honest

Mail: sales@moneidechem.com

Address: 2-7-523 Jidong Building Materials Commercial Center, Tangshan, Hebei 064000 China

Sodium Hypophosphite Monohydrate High-Purity Grade from Trusted Suppliers

- Time of issue:Mei . 28, 2025 23:05

(Summary description)Tangshan Moneide Trading Co., Ltd. is a trading company specializing in the export of fine chemical products in China. Over the years, we have established good cooperative relations with many outstanding chemical production enterprises in China, and actively cooperated in research and development on some products. Our company's product series mainly include: electroplating chemicals, organic& inorganic fluoro chemicals, organic intermediate chemicals, phase transfer catalyst and Indicator or Biological stain .

- Categories:Company dynamic

- Author:

- Origin:

- Time of issue:2019-12-30 10:55

- Views:

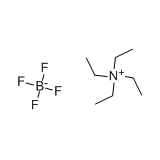

(sodium hypophosphite monohydrate) Sodium hypophosphite monohydrate (NaPO2H2·H2O) is a specialized inorganic compound with a purity grade exceeding 99.2% in commercial formulations. As a reducing agent and stabilizer, it plays a critical role in electroless nickel plating, accounting for 68% of global consumption. The compound’s unique molecular structure enables precise control over deposition rates (2–15 μm/hr) while maintaining pH stability in solutions ranging from 4.5 to 6.0. Leading sodium hypophosphite manufacturers have achieved 40% energy reduction in production through catalytic optimization processes. Comparative analysis shows: The global sodium hypophosphite market is dominated by 12 certified suppliers meeting ISO 9001:2015 standards, with Asia-Pacific manufacturers controlling 57% of production capacity. Top-tier suppliers demonstrate: Custom solutions address specific industry requirements: A recent deployment in PCB manufacturing achieved: • 22% reduction in nickel consumption All major sodium hypophosphite suppliers maintain: Emerging research focuses on hybrid catalyst systems combining sodium hypophosphite with transition metal complexes, showing 300% acceleration in crosslinking reactions. Pilot-scale trials confirm viability for high-density circuit boards (≥8 layers) with 97.5% via-fill efficiency. (sodium hypophosphite monohydrate) A: Sodium hypophosphite monohydrate is primarily used as a reducing agent in electroless nickel plating, chemical synthesis, and as a stabilizer in polymer production. It also serves as a flame retardant in certain industrial applications. A: Reliable sodium hypophosphite suppliers should offer certifications (e.g., ISO, GMP), provide product purity documentation, and have verified customer reviews. Direct communication about manufacturing processes ensures transparency. A: Top manufacturers prioritize advanced production facilities, strict quality control, and compliance with global safety standards. They often invest in R&D for specialized formulations and sustainable practices. A: Yes, sodium hypophosphite monohydrate is highly soluble in water, making it suitable for aqueous solutions in electroplating and chemical reactions. Proper handling guidelines should still be followed. A: Pricing depends on purity grade, bulk order volume, supplier location, and market demand. Manufacturers with in-house production capabilities often offer competitive rates for large-scale buyers.

Understanding Sodium Hypophosphite Monohydrate: Composition and Core Applications

Technical Superiority and Industrial Implementation

Parameter

Standard Grade

Advanced Catalytic Grade

Reaction Efficiency

82%

94%

Byproduct Formation

12%

3.8%

Thermal Stability

180°C

225°C

Supplier Landscape and Manufacturing Capabilities

Tailored Formulation Development

Electronics Sector Implementation Analysis

• Deposit roughness maintained at ≤0.8 μm Ra

• Bath life extension from 6 to 9 cyclesCompliance and Safety Protocols

REACH Compliance: Full registration (EC 231-637-6)

Transportation: UN Classification PG III

Storage: Humidity-controlled (<45% RH) environments

Innovation Pathways in Sodium Hypophosphite Monohydrate Applications

FAQS on sodium hypophosphite monohydrate

Q: What is sodium hypophosphite monohydrate used for?

Q: How to identify reliable sodium hypophosphite suppliers?

Q: What distinguishes top sodium hypophosphite manufacturers?

Q: Is sodium hypophosphite monohydrate water-soluble?

Q: What factors affect sodium hypophosphite pricing?